Contents

- 1 Understanding the Role of Pressure Switches in Fluid Control

- 2 The Principle Operation of Pressure Switches

- 3 Applications of Pressure Switches in Industry

- 4 Pressure Switch Installation and Maintenance

- 5 Choosing the Right Pressure Switch

- 6 Integration with Automation Systems

- 7 The Benefits of Proper Fluid Control

- 8 Expert Assistance and Consultation

Understanding the Role of Pressure Switches in Fluid Control

In the realm of fluid control systems, understanding the mechanism of a pressure switch is crucial for maintaining optimal performance within a vast array of industrial and domestic applications. These components play an essential role in monitoring and regulating the pressure of gases or liquids, ensuring systems operate safely and efficiently.

The Principle Operation of Pressure Switches

A pressure switch operates by opening or closing an electrical contact when a certain set fluid pressure has been reached. When pressure rises or falls to a specific threshold, the switch reacts, triggering an action that could be as simple as turning on a warning signal or as complex as starting or stopping a pump or compressor.

Different Types of Pressure Switches

Various types of pressure switches are employed in different contexts. From electromechanical designs with adjustable set points to solid-state switches that provide higher accuracy, choosing the right type is essential for any given application.

Applications of Pressure Switches in Industry

From HVAC systems to hydraulic and pneumatic systems, pressure switches are integral in various industries. In commercial settings, they are instrumental for ensuring processes like water treatment or air handling maintain consistency, preventing equipment failure or hazardous situations.

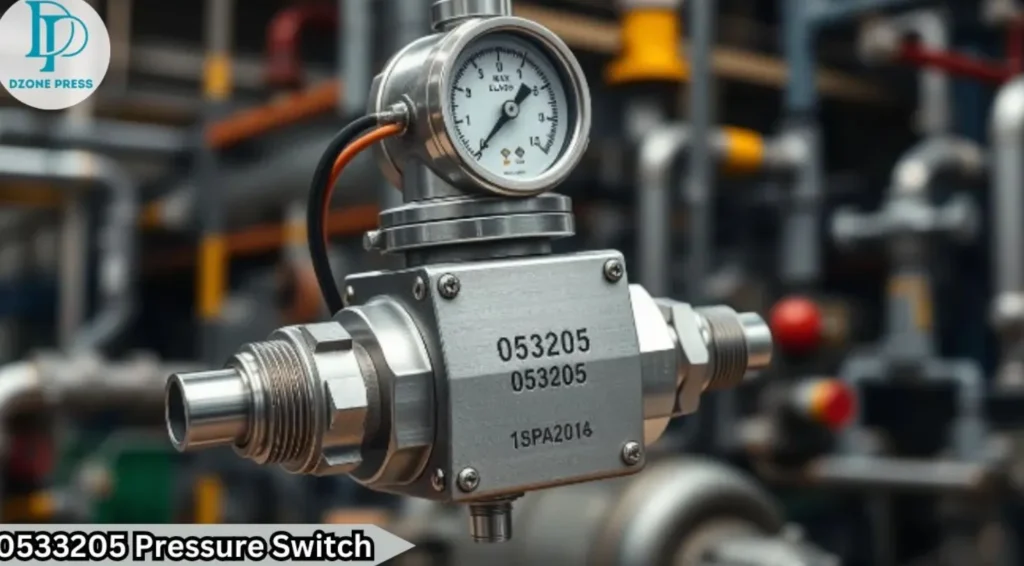

Materials and Design Specifications

Material selection for pressure switches is driven by the specific media they will encounter. Corrosion-resistant materials like stainless steel or specific plastics are often used for compatibility with different fluids and gases. Additionally, design specifications like pressure range and deadband are tailor-made for individual applications to ensure precision and durability.

Pressure Switch Installation and Maintenance

For a pressure switch to function effectively, proper installation is paramount. This includes calibration to the correct set points, ensuring it is compatible with the system’s pressure range, and conducting regular maintenance checks to prevent breakdown and leaks that could lead to inaccurate readings or system failures.

Safety Considerations and Compliance

When dealing with pressure control, safety is a top priority. Adhering to industry standards and regulations, like those laid out by the International Organization for Standardization (ISO), is non-negotiable to prevent accidents and assure the safety of workers and the environment.

Choosing the Right Pressure Switch

Procuring the right pressure switch involves understanding the specific demands of your fluid control system. Parameters such as pressure range, electrical ratings, size, and environmental resistance should drive your selection process. Suppliers like Valves Online have an extensive range of switches to suit various industry needs.

Mechanical vs. Electronic Pressure Switches

Mechanical pressure switches, being more cost-effective and straightforward in design, are prevalent in industries where digital equipment’s complexity is not needed. In contrast, electronic pressure switches offer higher accuracy, easier integration with digital control systems, and greater customization for complex applications.

Integration with Automation Systems

A pressure switch is often a critical component within an automated system. Integration with a system’s control logic enables automated adjustments in response to pressure changes, enhancing the reliability and responsiveness of fluid control systems, whether they monitor the water pressure in a municipal supply or the hydraulic pressure in an automated manufacturing process.

The Future of Pressure Control Technologies

Advancement in pressure control technologies focuses on integrated systems that can predict failures, adjust to changing conditions in real-time, and offer data analytics to improve system performance over time. As industries become more data-driven, the intelligent pressure switch is the frontier of innovation, signaling a significant leap in the efficiency of fluid control management.

The Benefits of Proper Fluid Control

Mastering fluid control with the appropriate pressure switches leads to a multitude of benefits. It can translate into increased operational lifespan of equipment, energy savings, improved safety, and reduced downtime. In essence, attention to detail in pressure control can mean a significant return on investment for businesses.

Case Studies and Real-World Scenarios

Analyzing case studies where pressure switches have averted system failures or significantly enhanced performance can provide tangible insights. Examples from industries such as oil and gas, chemical processing, and water management illustrate the profound impact of well-chosen pressure monitoring and control systems.

Expert Assistance and Consultation

Finding the right solution for fluid control can be complex, and seeking expert advice is often a wise choice. Professional consultants and suppliers can provide valuable insight into the specific needs of an application, aiding in the selection of the best pressure switch for the task.

Enhancing System Efficiency with the Right Pressure Switch

In concluding, the importance of a well-chosen pressure switch cannot be overstated in the world of fluid control. With the right switch in place, systems can be fine-tuned to perform at peak efficiency, conserving resources while safeguarding investments. This essential guide serves not only as a practical introduction but as a resource for mastery in the art of fluid control.